OverView

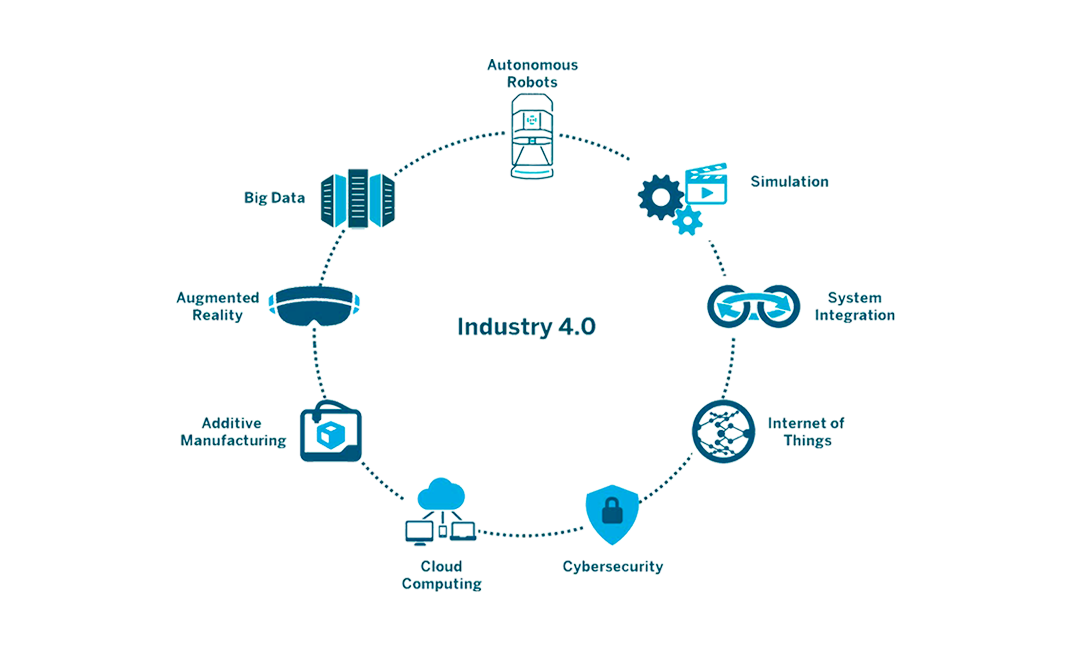

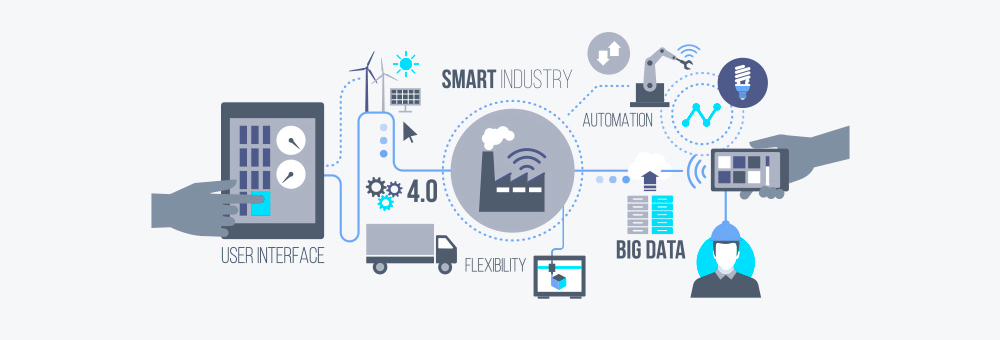

Industry 4.0, is the marriage of IT and manufacturing operations – the maturation of digital technology in the manufacturing industry. It is holistic shift from centralized to decentralized manufacturing, which requires the adaptation of processes, talent, business structure and technology. Technology, including advanced robotics and artificial intelligence, sophisticated sensors, cloud computing, IOT, data capture and analytics, and digital fabrication, all coalescing into the ushering of the next industrial revolution.

As the number of smart devices and amount of data captured, analyzed, and stored grows, connectivity and communication will only become more important. Both within the enterprise and to third-party partners, companies will need their data to be shareable and compatible to enable a higher level of operation.

IoT is the bridge that allows the granular insights provided by high tech solutions to join together into a coherent, enterprise-level picture for modern manufacturers. IoT manufacturing enables virtual tracking of capital assets, processes, resources and products. This gives enterprises full visibility, which streamlines business processes and optimizes supply and demand.

When implemented correctly, decision-makers will be equipped with more and better information, automated processes, and the ability to intervene on a predictive or preventive basis to avoid downtime or any other issues that might slow down production output.

Additive manufacturing

This continues to become increasingly important for small-batch applications or for the production of individual parts or personalised products. This will be used either directly with the customer or by suppliers to improve designs with increased performance, flexibility, and cost effectiveness.

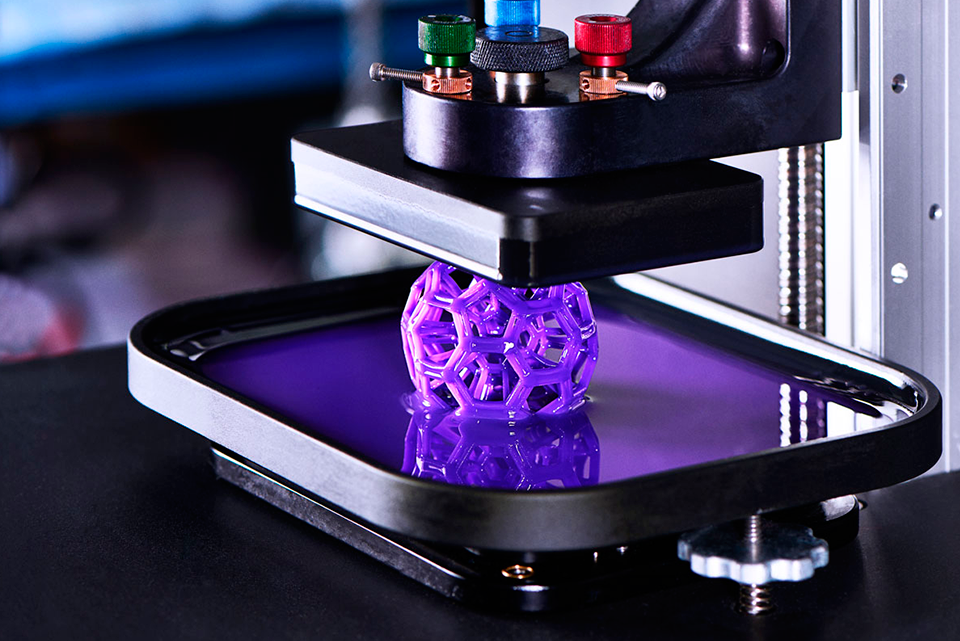

3D printing

3D printing, also known as additive manufacturing (AM), refers to the processes used to synthesise a three dimensional object in which successive layers of material are formed under computer control to create an object. 3D printing technology may have significant impact on several touch points in the auto value chain including the design cycle, replacement parts for customer service and even customer co-design of their vehicles.

Additive manufacturing enables a continuous factory production for individual parts and thus, prevents losses that take place during a normal production process. Also, speed is another factor to take into consideration, because a faster process means more continuity to the design and the overall development process.

Additive manufacturing enables a continuous factory production for individual parts and thus, prevents losses that take place during a normal production process. Also, speed is another factor to take into consideration, because a faster process means more continuity to the design and the overall development process. When it comes to design flexibility the possibilities are far vaster with 3D printing.

Adaptive Manufacturing

The ability to quickly adapt operations, supply chains and products is essential to achieving manufacturing excellence in today's globally competitive markets.

Most of the time, basic automated systems use robots. These are repeatable, but not really accurate. To overcome this lack of accuracy, an adaptive process needs to be implemented. Adaptive means that the system is able to measure and adapt its process in real-time.

The benefits from adaptive automation are improvement of production’s quality and consistency, reduction of abrasive consumption and therefore its cost, better ergonomics and safety and more stable throughput. Furthermore, since real adaptive systems consider parts variations, the parts can be less precise before they enter the automated system and still get through quality afterwards.

Our Services & Solution

We develop data capture, communication and control mechanisms to connect machines, tools, systems and even parts being manufactured to optimise production costs, improve product quality and make manufacturing processes more robust.